SYBR 6315/VA201 High Temperature Bearings

High-temperature applications demand bearings that can withstand extreme heat without sacrificing performance, durability or reliability. Our high temperature ball bearings provide benefits including reduced amount of time spent on upkeep of machines and more trustworthy production. High temperature bearings are manufactured specifically for applications that run in harsh environments where machines can't be greased as in low or room temperature applications. We carry inch and metric size high-temperature bearings that maintain exceptional performance at temperatures to 400°F (204°C) and beyond. These bearings which are ideal for extreme high temperature applications are designed to provide high reliability, longer life and reduce machine operating costs.

Our high-temperature bearings are manufactured from heat-stabilized stainless steels and ceramic materials. We also improve the high-temperature performance of our bearings through features such as:

Perfluorinated polyether (PFPE) and other high-temperature lubricants

“Loose” internal clearances to accommodate larger coefficients of expansion

High temperature resistant bearings Profile:

High temperature resistant bearing: the first and most primary is the tolerance for high temperature.There are many kinds of, high-temperature bearing according to different needs, different environment, can install different types of bearings.

Category:

High temperature resistant bearing from structural process can be divided into: common structural resistance to high temperature bearing resistance to high temperature and special structure bearing.

Usage environment:

High temperature bearing is widely used in metallurgy, kiln, glass, paint spraying equipment or blast furnace burden and other high temperature operating machinery.

High temperature resistant general type:

Ordinary structure: high temperature resistant bearing mainly refers to is in accordance with the commonly used bearing structure, using high temperature resistant materials such as resistance to high temperature bearing steel, design of the bearing, mainly has high temperature resistant self-aligning ball bearings, such as resistance to high temperature deep groove ball bearings.

Resistance to high temperature deep groove ball bearings:

Internal no retainer, only rolling body composition; can meet Around 300 ℃ working conditions, according to the common tolerance in production, and the clearance is greater than the ordinary bearing, so usually are not suitable for high-speed operation situation, belong to high temperature and low speed bearings, usually within 200 RPM speed run for a long time.

High temperature resistant special type:

Special high temperature resistant bearing structure, not only material with high temperature resistant materials, more from the structure to realize automatic clearance under the environment of high temperature compensation, such as spiral spring bearing.

Operating Requirement:

During normal operation, the bearing cannot be jammed and noise of the abnormal phenomenon, at the same time, imported high temperature resistant bearing need to withstand the vibration, impact, the influence of such factors as bearing materials should have the performance of wear resistance, permeability resistance and corrosion resistance.

Material Selection:

According to the special working condition of imported high temperature resistant bearing, ring and ball material should have high temperature resistance, corrosion resistance, wear resistance, the characteristics of non-magnetic.Recommended for G52 # alloy ring material, the ball material for Si3N4 ceramic or metal.

High temperature bearing cage:

Cage is TS60000 type, used in high-speed; no cage full of rolling elements T60000 type (T60000 type ball gap; T60000B type No ball gap) and self-lubricating T60000C type, for low-speed 100 <r / min , or horizontally mounted speed, T60000 type single ball raceway full of (A type ball gap, B-no ball gap), load capacity. Product specification range: 10≤d≤500. High temperature to 200 ~ 800 ℃ seven, main radial load, also can withstand axial load in either direction.

| HIGH TEMPERATURE SINGLE ROW DEEP GROOVE BALL BEARING | |||

| 6300-2Z/VA201 | 6305-2Z/VA228 | 6309-2Z/VA208 | 6313/VA201 |

| 6201/VA201 | 6006-2Z/VA208 | 6210/VA201 | 6313-2Z/VA208 |

| 6201-2Z/VA201 | 6206/VA201 | 6210-2Z/VA201 | 6214/VA201 |

| 6201-2Z/VA228 | 6206-2Z/VA201 | 6210-2Z/VA208 | 6214-2Z/VA208 |

| 6202/VA201 | 6206-2Z/VA208 | 6210-2Z/VA228 | 6314/VA201 |

| 6202-2Z/VA201 | 6206-2Z/VA228 | 6310/VA201 | 6314-2Z/VA208 |

| 6202-2Z/VA228 | 6306/VA201 | 6310-2Z/VA201 | 6215/VA201 |

| 6003/VA201 | 6306-2Z/VA208 | 6310-2Z/VA208 | 6215-2Z/VA201 |

| 6203/VA201 | 6306-2Z/VA228 | 6310-2Z/VA228 | 6215-2Z/VA208 |

| 6203-2Z/VA201 | 6207/VA201 | 6011-2Z/VA208 | 6215-2Z/VA228 |

| 6203-2Z/VA228 | 6207-2Z/VA201 | 6211/VA201 | 6315/VA201 |

| 6004-2Z/VA208 | 6207-2Z/VA208 | 6211-2Z/VA201 | 6315-2Z/VA208 |

| 6204/VA201 | 6207-2Z/VA228 | 6211-2Z/VA208 | 6216-2Z/VA208 |

| 6204-2Z/VA201 | 6307/VA201 | 6211-2Z/VA228 | 63162Z/VA208 |

| 6204-2Z/VA228 | 6307-2Z/VA208 | 6311/VA201 | 6217/VA201 |

| 6304/VA201 | 6008-2Z/VA208 | 6311-2Z/VA208 | 6217-2Z/VA208 |

| 6304-2Z/VA201 | 6208/VA201 | 6212/VA201 | 6218-2Z/VA228 |

| 6304-2Z/VA208 | 6208-2Z/VA201 | 6212-2Z/VA201 | 6219/VA201 |

| 6005/VA201 | 6208-2Z/VA208 | 6212-2Z/VA208 | 6219-2Z/VA208 |

| 6005-2Z/VA201 | 6208-2Z/VA228 | 6212-2Z/VA228 | 6219-2Z/VA228 |

| 6005-2Z/VA208 | 6209/VA201 | 6312/VA201 | 6020-2Z/VA228 |

| 6205/VA201 | 6209-2Z/VA201 | 6312-2Z/VA208 | 6220/VA201 |

| 6205-2Z/VA201 | 6209-2Z/VA208 | 6213/VA201 | 6220-2Z/VA208 |

| 6205-2Z/VA228 | 6209-2Z/VA228 | 6213-2Z/VA208 | 6220-2Z/VA228 |

| 6305/VA201 | 6309/VA201 | 6213-2Z/VA228 | 6024-2Z/VA208 |

High Temperature Bearings Application:

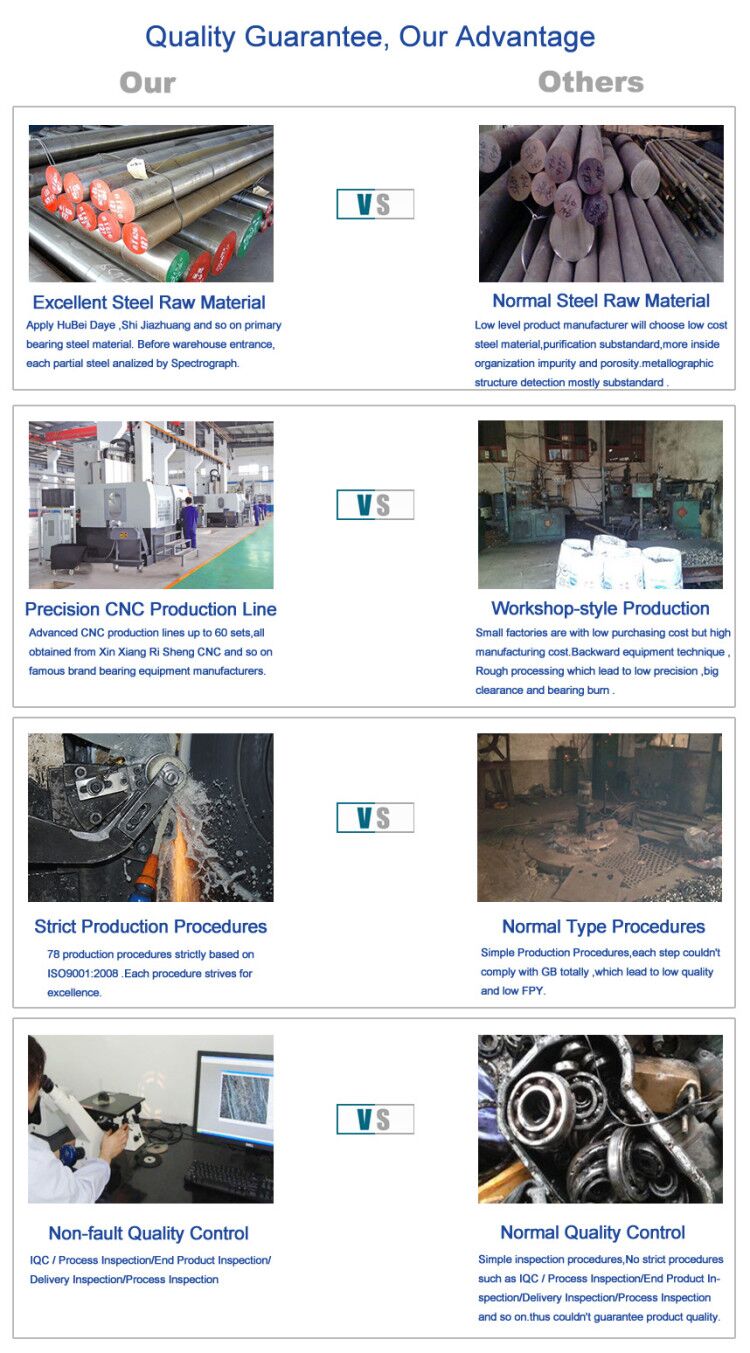

Our advantages

Customers with us