INSOCOAT Bearings models

Feature

Features:

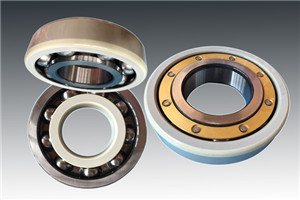

INSOCOAT bearings are designed to prevent current from passing through the bearing. The bearings are a very cost-effective solution compared with other insulation methods. By integrating the insulating properties into the bearing, INSOCOAT bearings can improve reliability and increase machine up time by virtually eliminating the problem of electrical erosion.

An INSOCOAT bearing is a standard bearing that has the external surfaces of its inner or outer ring plasma-sprayed with an oxide to form a coating. The coating is sealed with a resin to protect against the conductive effects of water and moisture.

The basic coating can withstand voltages up to 1 000 V DC. However, coatings to withstand voltages up to 2 000, or even 3 000 V DC, can be supplied on request.

Parameter:

| VL0241 | INSOCOAT bearings with a coated outer ring |

| VL2071 | INSOCOAT bearings with a coated inner ring |

The standard assortment of INSOCOAT bearings listed here constitutes the most commonly used sizes and variants of:

■ single row deep groove ball bearings

Depending on their size, INSOCOAT deep groove ball bearings are fitted with one of the following cages:

a stamped steel cage, riveted, ball center (no designation suffix)

a machined brass cage, riveted, ball center (designation suffix M)

■ single row cylindrical roller bearings

INSOCOAT cylindrical roller bearings are fitted with one of the following cages:

a glass fiber reinforced PA66 cage, window-type, roller (designation suffix P)

a machined brass cage, riveted, roller (designation suffix M)

a machined brass cage, window-type, inner or outer ring depending on the bearing design (designation suffix ML)